DIFFERENCE BETWEEN INDUSTRIAL ETHERNET AND REGULAR ETHERNET

Introduction

Ethernet technology can be separated into two primary categories regarding their intended use: Industrial Ethernet and regular Ethernet. Industrial Ethernet essentially refers to Ethernet that is equipped to operate efficiently in a rugged industrial environment. “Regular” Ethernet, on the other hand, is Ethernet that is designed for commercial use. Attempting to use regular Ethernet devices in an industrial setting can greatly reduce the efficiency and quality of a network. As such, it is important to recognize and identify the many ways that these two types of Ethernet differ from one another. To gain a better understanding of the difference between industrial Ethernet and regular Ethernet, continue reading.

Application Requirements

One of the main differences between industrial Ethernet and regular Ethernet is their application requirements. The fundamental purpose of industrial Ethernet differs greatly from commercial Ethernet. Industrial Ethernet is created for mission-critical purposes where determinism and real-time control is vital. Commercial Ethernet does not inherently provide such deterministic performance or real-time communication, and thus cannot meet the application requirements of industrial usage.

Operating Conditions

Another substantial difference between industrial Ethernet and regular Ethernet is the operating conditions of each type of technology. Regular Ethernet is designed to work in commercial networking applications such as data centers or office buildings where it will be located in an indoor, temperature-controlled, clean, and stable environment. Industrial Ethernet, however, was designed to work efficiently in rugged industrial environments. As such, industrial Ethernet must be able to stand up to much harsher environmental demands, such as:

- Extremely high or low temperatures

- Exposure to water

- Exposure to high winds

- Exposure to high humidity levels

- Exposure to UV Rays

- Exposure to electromagnetic environments

Because commercial Ethernet technology is not designed to withstand such harsh operating conditions, implementing it in an industrial setting will likely result in substantial damage. As a result, other negative repercussions such as downtime or critical data loss can occur.

Blog Posts

Thermal Camera Selection

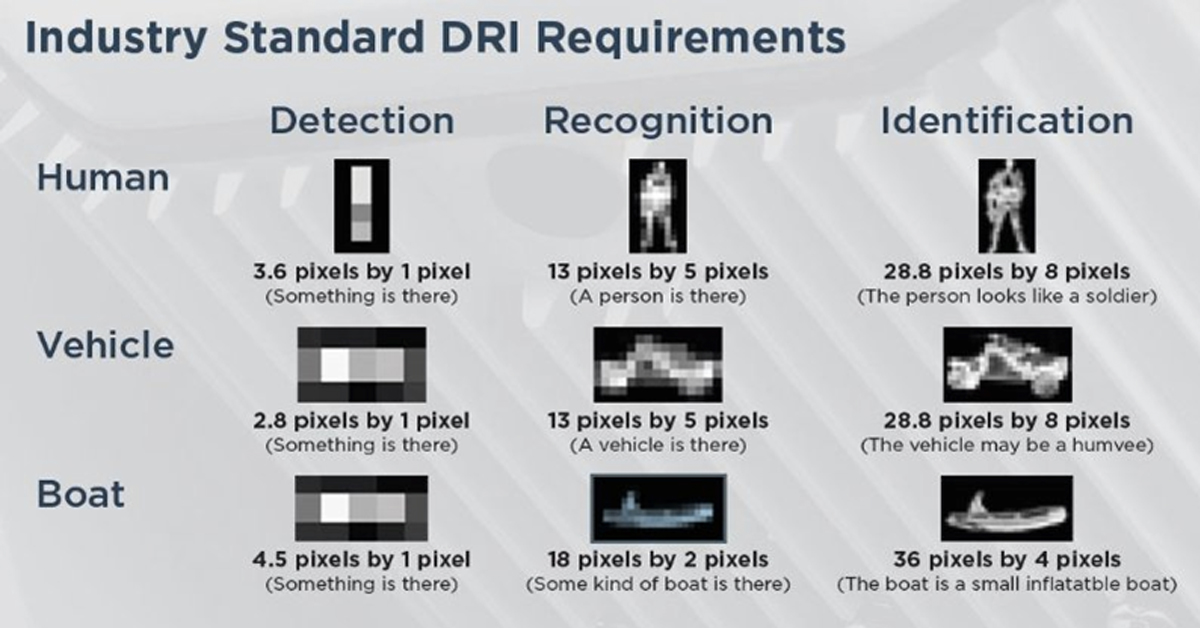

How Far Can I See?

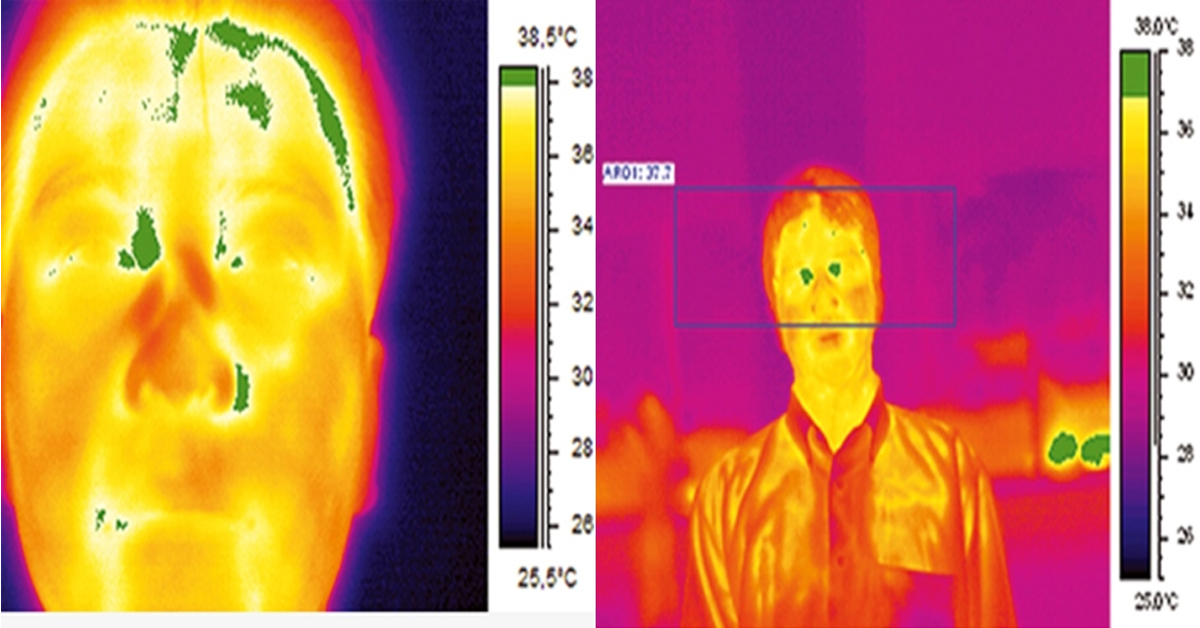

How Should Human Temperature Be Measured?

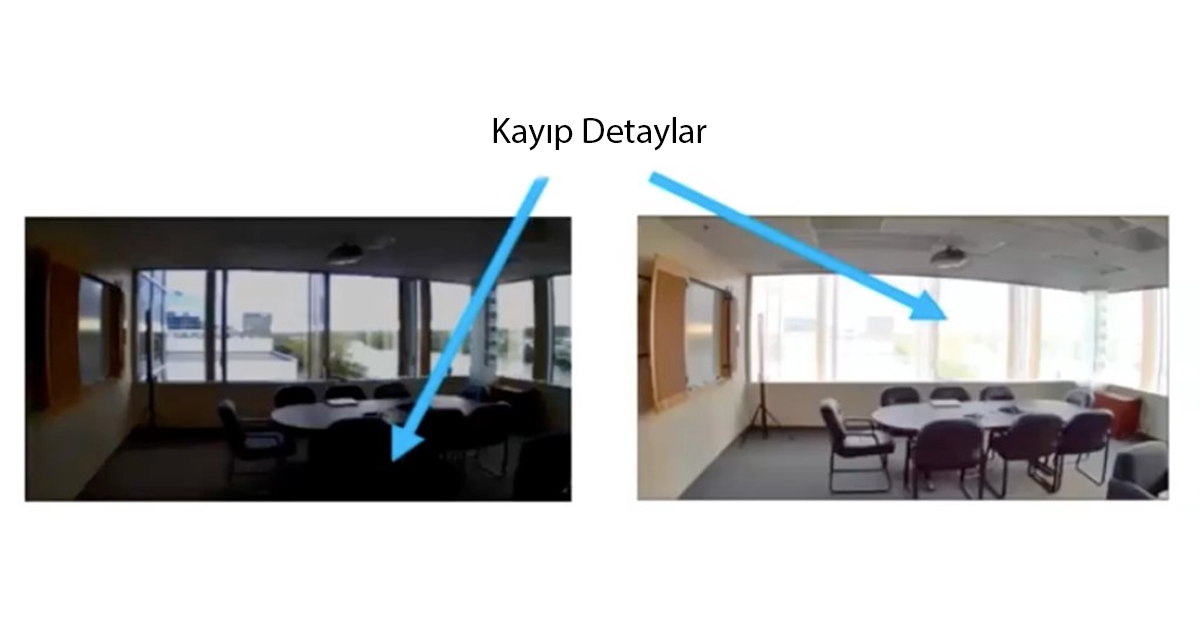

What is Wide Dynamic Range?

MYNOISE AUDIO MIXER REVIEW

WHAT IS A WIRELESS DISTRIBUTION SYSTEM?

POE VS. POE+ VS. POE++: CHOOSING THE RIGHT INDUSTRIAL ETHERNET SWITCH FOR YOU

INDUSTRY-LEADING INDUSTRIAL ETHERNET SWITCHES

UNDERSTANDING WHAT THE INDUSTRIAL INTERNET OF THINGS IS

THE DIFFERENCE BETWEEN A HUB, SWITCH, & ROUTER

5 Benefits of Thermal Imaging Cameras

DIFFERENCE BETWEEN INDUSTRIAL ETHERNET AND REGULAR ETHERNET

INDUSTRIAL NETWORKING EQUIPMENT USED FOR AUTONOMOUS VEHICLES

CYBERSECURITY: PROTECTING INDUSTRIAL CONTROL SYSTEMS

HOW INDUSTRIAL NETWORKING CAN PROVIDE SECURITY FROM DRONES

.webp)

Thermal Cameras Reveal How to Keep Your Home Cool During a Heat Wave

FLıR ONE PRO

.png)

Unmatched Maritime Awareness with Cooled Thermal Imaging

.png)

What Is the Right Handheld Thermal Camera for You?

.png)

Camera Resolution and Range

.png)

Special Applications for Marine Cameras

.png)

What’s The Difference between Thermal Imaging and Night Vision?

.png)

Can Thermal Imaging See Through Fog and Rain?

Which Cx-Series Camera Is Right for You?

.png)

What is MSX®?

Five Reasons Maritime First Responders Need Thermal Imaging

.png)

3 Distinguishing Features of Superior Thermal Cameras

.png)

Determine Which Visible and Thermal Security Cameras You Need

Bullet vs. PTZ vs. Dome: Which Security Camera Is Right for You?

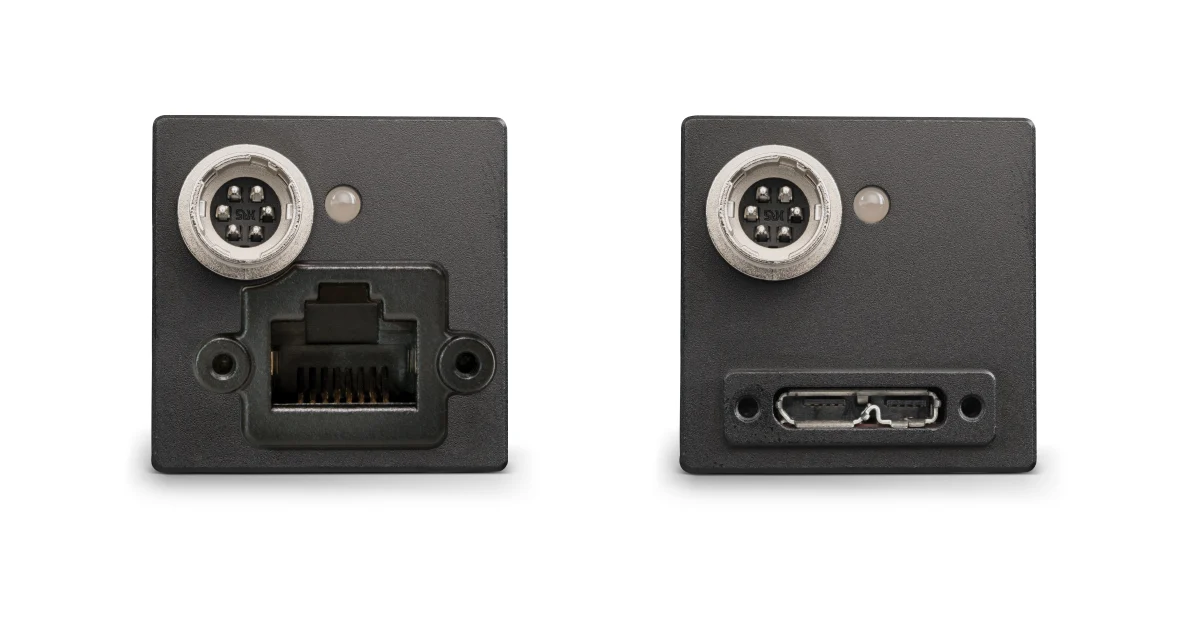

Interfaces for Machine Vision

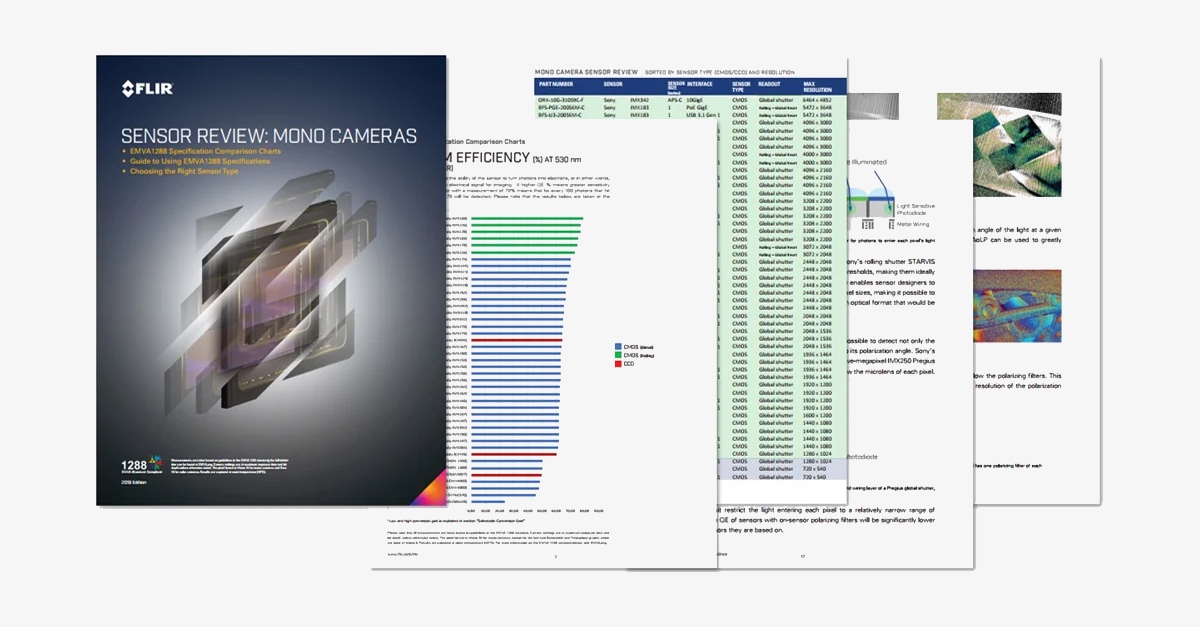

Machine Vision Sensor Review

.png)

Teledyne FLIR, the Industry Leader, Launches Boson +, a Long-Wave Infrared Thermal Imager Module with an Accuracy of Less Than 20 mK

.png)

Whitepaper: IP-Based Security Convergence

.png)

3 Technologies Transforming Safe Cities into Smart Cities

.png)

Insights from the Field: Ensuring Workplace Safety Using Thermal Camera Screening for Entry Control

Thermal Night Vision as a Force Multiplier

Can Thermal Imaging See Through Walls? And Other Common Questions

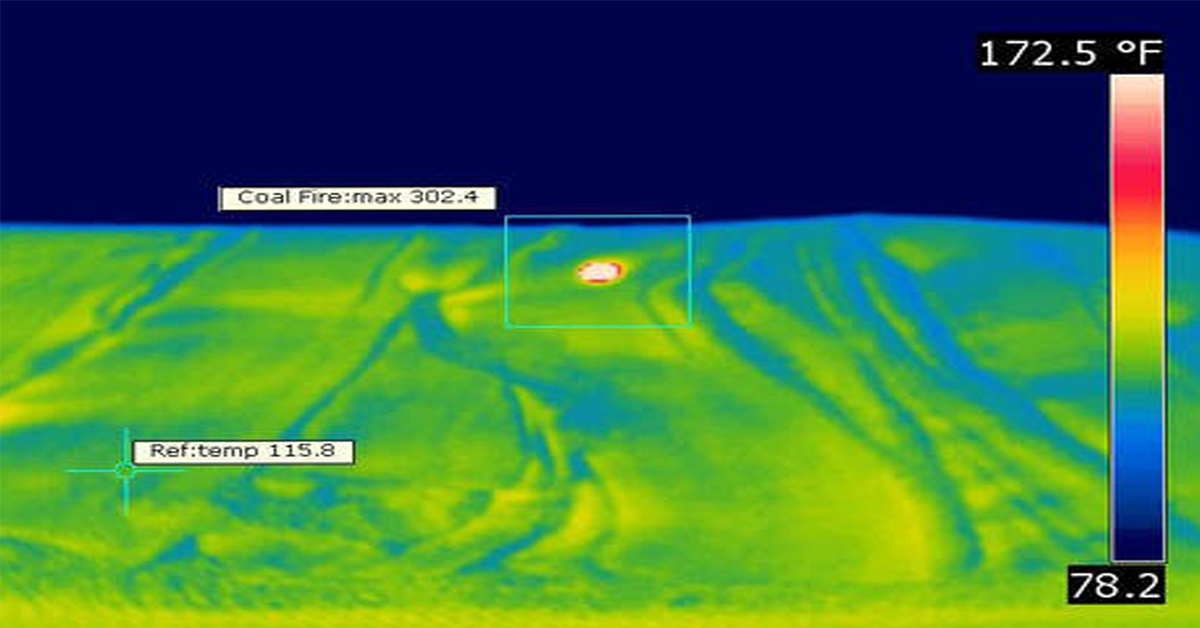

Application Spotlight: Early Fire Detection for Rapid Heat Generation

Protect Personnel and Equipment by Detecting Early Signs of Fire

Teledyne FLIR Launches A500f/A700f Cameras for Fire Detection and Condition Monitoring

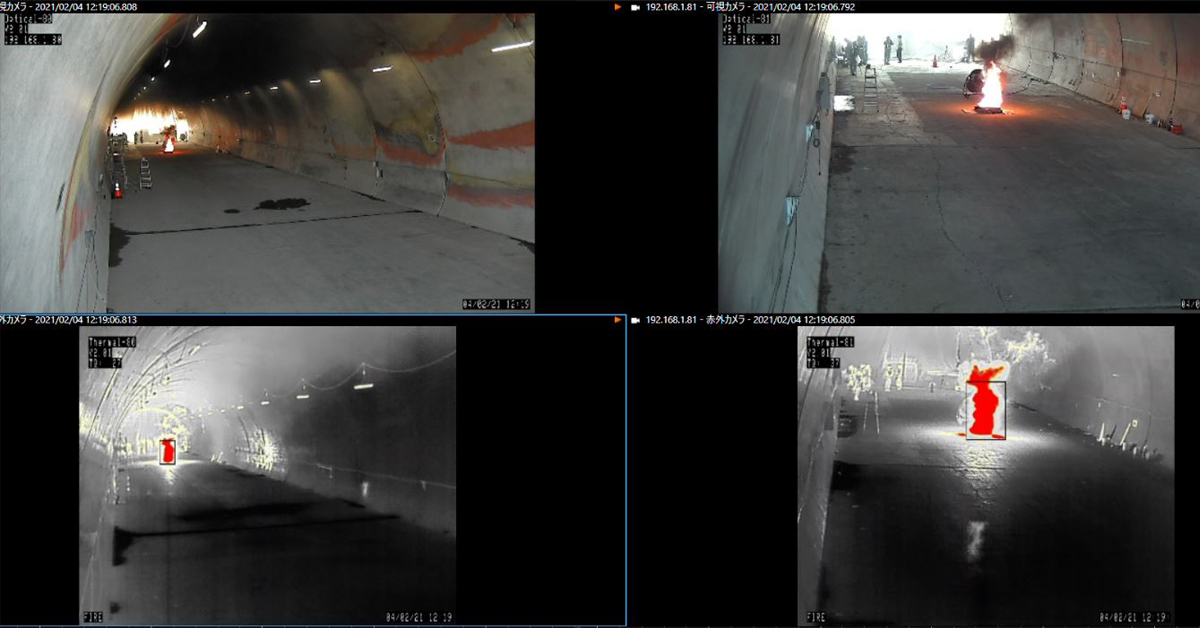

Thermal Imaging Cameras Help Guarantee Fire Safety in Tunnels

Thermal Imaging Cameras Help to Prevent Fires

ITS-Series Dual AID Surpasses Standards for Fire Detection Systems in Japan

How Layering Multispectral PTZ Cameras and Radars Improve Perimeter Protection

POWER REMOTE RESET TECHNOLOGY - PRRT

Why Yacht Owners are Adding Thermal Imaging Cameras to Minimise the Risk of Lithium-Ion Battery Fires?

.png)

Intelligent Transportation Systems

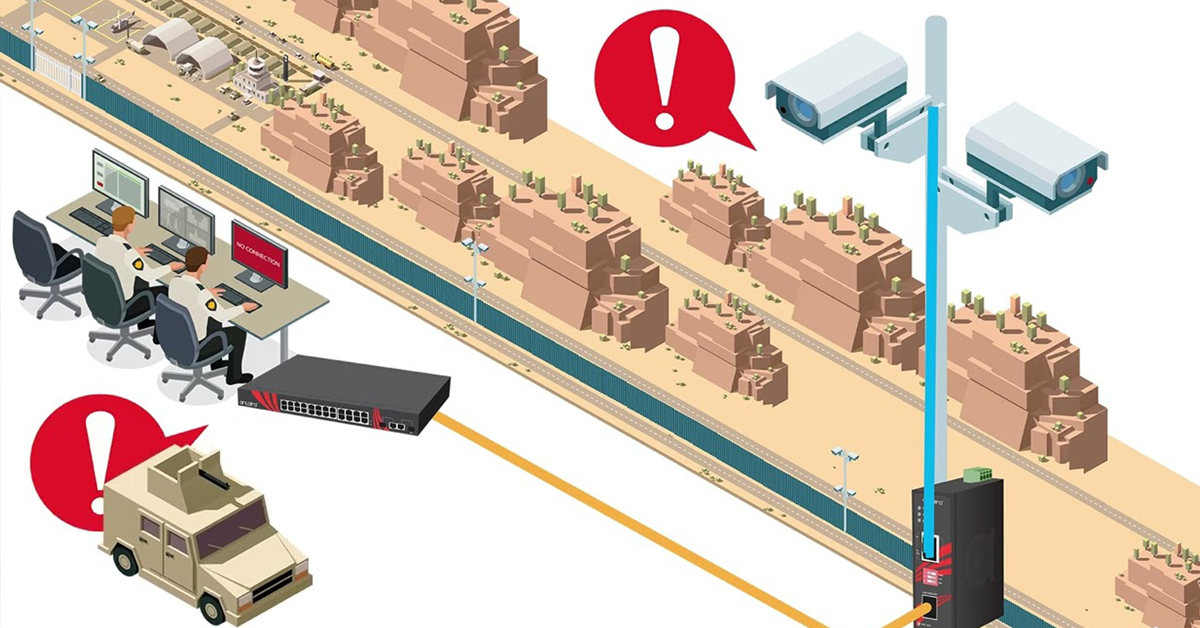

Best Practices Guide for Perimeter Security Applications

Protect Pedestrians, Bicyclists and More with Thermal Smart Sensors

White Paper: Application of Ground-Based Security Radar to Perimeter Systems

What is Thermal Leakage and How to Reduce Its Risks

Battery Inspection Using Advanced Thermography

Providing ire Protection for Lithium Battery Storage

The Power of Thermal Imaging

.png)

Why Panel PCs Are Perfect For Industrial Applications?

Teledyne DALSA

.png)

Advantages of Virtual Barrier Video Analytics for Perimeter Security Systems

.png)

.png)

NASA Takes the Teledyne FLIR Boson Thermal Camera Module Out of this World

.png)

Port Security Enhancement: DP World Yarımca's Trust in FLIR Security Solutions for Effective and Safe Port Operations

.png)

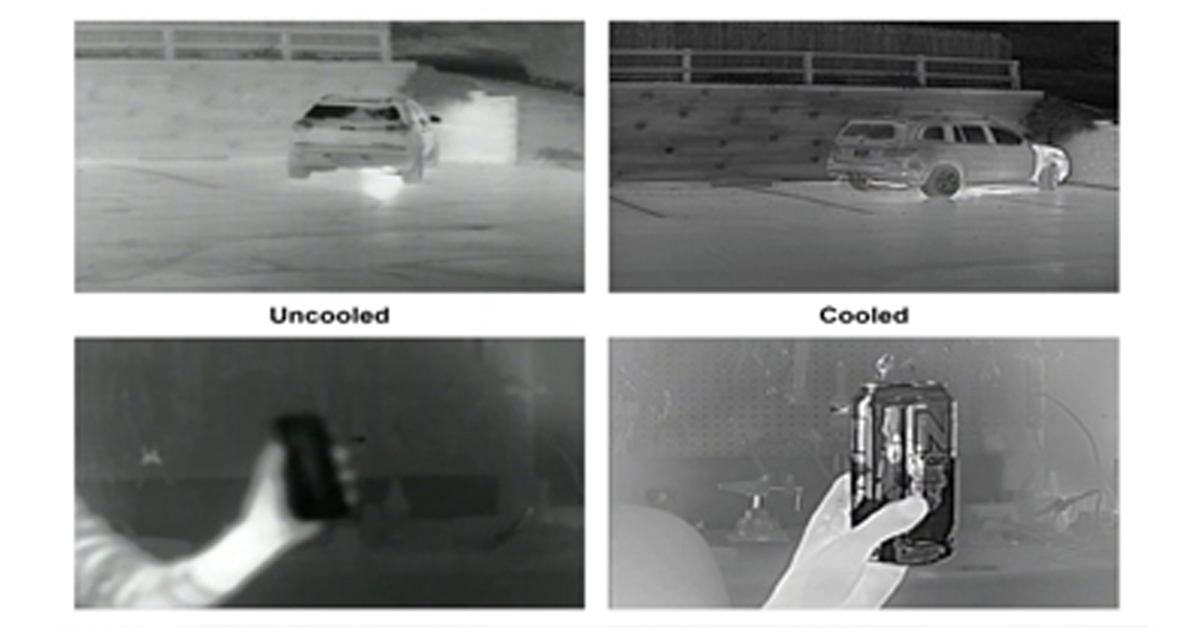

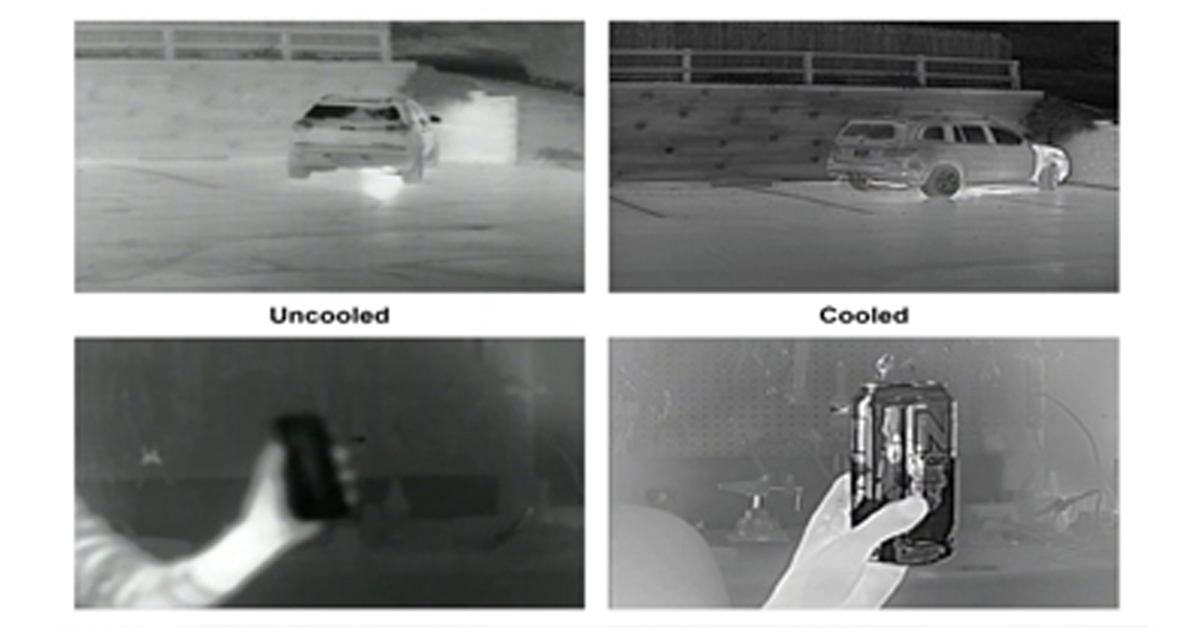

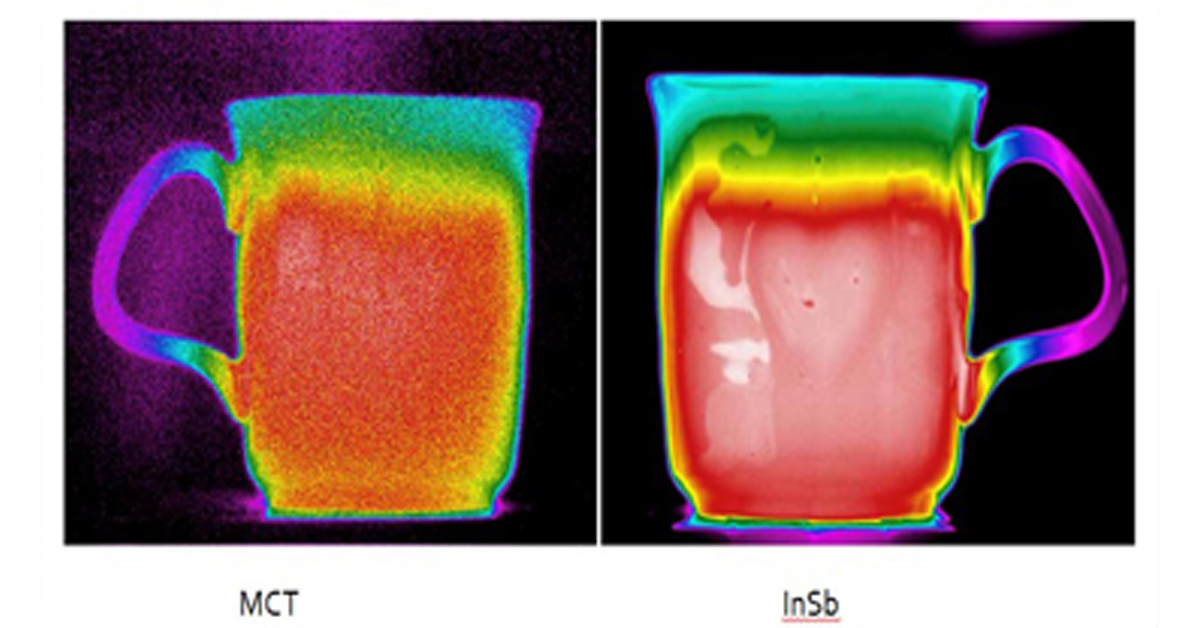

The Importance of Thermal Sensitivity (NETD) for Detection Accuracy

.png)

Bosphorus Boat Show 2025: The Meeting Point of the Maritime World

Application Spotlight: Critical Asset Monitoring for Thermal Conditions

.png)

Thermal Imaging for Marine Firefighting

Imaging in Mobile Mapping

.png)

Using Thermal Imaging for Oil Spill Detection

Five Reasons Maritime First Responders Need Thermal Imaging

Case Study: Tackling Compressed Air Leaks in Automotive Parts Manufacturing with Acoustic Imaging

Thermal Night Vision as a Force Multiplier

.png)

Line Scan Contact Image Sensor - AxCIS

Beyond Resolution: What Really Makes a Camera System Work for Mobile Mapping

.png)

Multispectral Marine Cameras for USV Applications

.png)

Stabilizing FLIR Cameras for Smooth Viewing in Rough Waters

(1).png)